Properties

At Underwater Windows®, we have a wide range of acrylic products for swimming pools. The most common products can be found below. We also supply curved underwater windows (tunnels) with corner or longitudinal bonding, allowing windows to be made longer than the standard maximum length of 7800 mm.

We offer three types of underwater windows, all made of original Plexiglas® - crystal clear, UV-resistant and indestructibly strong:

- Overflow or open top windows - give an endless effect as the top of the window remains open.

- Four-sided underwater or bottom windows - provide spectacular light and extraordinary views.

- Round underwater windows - popular for observation and unique designs.

Properties

Overflow or open top windows

These acrylic underwater windows are fixed into the pool on three sides, while the top of the window is "open". This creates a spectacular endless effect.

- Maximum one-piece standard dimensions: 7800 mm x 3000 mm

- With transparent bonding, dimensions can be be infinitely enlarged

Properties

Four-sided underwater or bottom windows

Four-sided windows create a unique effect in any pool. Think of sunbeams penetrating or a surprising view through to the outside.

- Standard dimensions:

up to 7800 mm x 3000 mm - Suitable for both wall and floor applications

Properties

Round underwater windows

Round windows are very popular, especially for observation during swimming. They can be integrated into both the wall and the bottom of the pool.

- Standard up to a diameter of 3000 mm

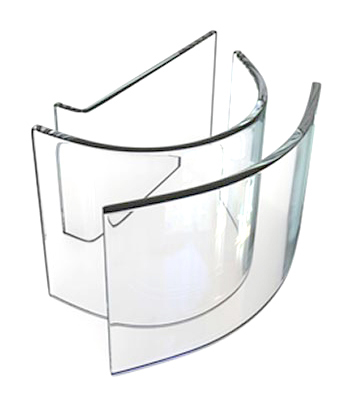

Special acrylic windows

Corner underwater windows, long overflow windows or curved underwater windows - at Underwater Windows® we make them fully customised, in any length (provided the application allows).

These acrylic windows are installed through a 5-component chemical bonding joined together, both in our workshop and on site. The joint is completely transparent and polished, making it virtually invisible.

- Windows up to a length of 3000 mm available with fast lead time

- Strength calculation tailored to the depth of the application

- Takes into account additional loads from humans, animals or changing water levels

Properties

| Feature | Value | Comment |

|---|---|---|

| Light transmission | ~92% | Higher than standard glass |

| Density | 1.19 g/cm³ | Lighter than glass (2.5 g/cm³) |

| Tensile strength | approx. 70 MPa | High mechanical strength |

| Impact resistance | 11x higher than glass | Depending on thickness |

| Temperature range | -40°C to +80°C | Briefly up to 90°C |

| UV resistance | Very high | No yellowing |

| Water absorption (24h) | 0,3% | Very low |

| Chemical resistance | Highly resistant to chlorine and salt water | Not resistant to strong solvents |

| Max. panel dimensions | Up to approx. 3 x 6 metres | Depending on thickness and design |

| Edit | CNC milling, hot bending, polishing | Suitable for customisation |

Perspex, Plexiglas® , PMMA, Acrylic

Technical advantages of Plexiglas® for made-to-measure swimming pool windows

At Underwater Windows, we deliberately choose Plexiglas® (PMMA - Polymethylmethacrylate) as the material for our transparent pool windows. This material combines clarity, strength and durability in a way that perfectly suits the high demands of both private and professional use.

Light transmission and optical purity

Plexiglas® has an exceptionally high light transmission of about 92%, which is even higher than standard glass. This ensures a crystal-clear view underwater, free of distortions or turbidity. Thanks to the low internal stresses, even thicker panels remain optically clean, preventing distortion and maintaining a true-to-life view.

UV and weather resistance

One of the main reasons for choosing Plexiglas® is its built-in UV resistance. Whereas other materials can yellow over time or become brittle from sunlight, Plexiglas® retains its brightness and mechanical properties for years. Because the UV stabilisation is in the material itself, there is no need for an additional coating that can wear off or damage it.

Mechanical strength and safety

Plexiglas® is up to 11 times more impact-resistant than glass of equal thickness, making it ideally suited for applications under high hydrostatic pressure, such as in deep swimming pools. If damage does occur, Plexiglas® does not break into sharp shards, significantly increasing safety.

Chemical resistance

The material is resistant to chlorine and salt water, and less susceptible to attack by pool chemicals than many other plastics. In addition, it is easy to clean without losing clarity or dulling the surface.

Design freedom and customisation

Plexiglas® is particularly versatile in processing. It can be precision milled, hot bent and polished to a high gloss. This allows straight as well as curved and fully customised shapes. Large panel sizes are also among the options, ensuring panoramic underwater views without annoying seams.

Service life and maintenance

Plexiglas® has a very long lifespan and retains its strength and clarity, even under severe weather and usage conditions. With minimal maintenance - such as periodic cleaning with gentle, non-abrasive agents - the material remains in top condition for years and offers a lasting bright appearance.